SSD Static Elimination Equipment: What are the hazards of static electricity in industry?

- Popularity: 2699

- Date: 2023-07-01

Static Electricity Hazards in Industry

Static electricity is a common phenomenon in various industrial settings, and it poses significant hazards that can impact both personnel and equipment. To mitigate these risks, SSD (Static Static Dissipative) Static Elimination Equipment is employed. Let's explore the hazards associated with static electricity in industry and the role of SSD Static Elimination Equipment in preventing accidents.

Hazards of Static Electricity in Industry

1. Fire and Explosion: One of the most critical hazards of static electricity is the potential for fires and explosions. In industries handling flammable gases, liquids, or dust, static sparks can ignite these substances, leading to catastrophic incidents.

2. Damage to Electronics: Static discharge can damage sensitive electronic components and equipment. This is a significant concern in industries like electronics manufacturing, where even a small discharge can ruin expensive components.

3. Product Contamination: Static electricity can attract dust and other particles, causing product contamination. In industries such as pharmaceuticals and food processing, contamination can lead to health risks and product recalls.

4. Personnel Safety: Workers in industrial environments are at risk of receiving painful and sometimes dangerous static shocks. These shocks can lead to injuries, distractions, and decreased productivity.

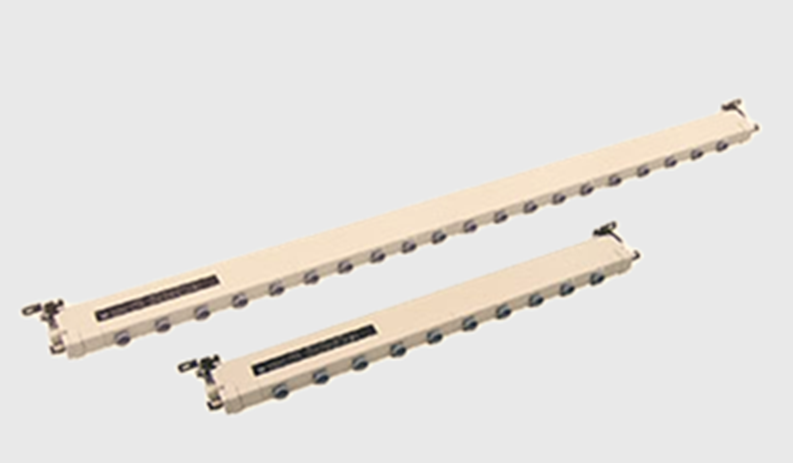

SSD Static Elimination Equipment

SSD Static Elimination Equipment is designed to mitigate the hazards of static electricity in industrial settings. These devices work by neutralizing or dissipating static charges, reducing the risk of sparks and shocks. Some common types of SSD equipment include ionizers, grounding systems, and antistatic materials.

Ionizers: Ionizers release ions that neutralize static charges on surfaces and in the air. They are often used in cleanroom environments and electronic assembly to prevent product defects caused by static discharge.

Grounding Systems: Proper grounding of equipment and personnel is essential to prevent static buildup. Grounding systems ensure that any static charge is safely dissipated into the ground, reducing the risk of sparking.

Antistatic Materials: Antistatic materials, such as clothing and flooring, are used to minimize the generation of static charges. They are commonly employed in industries where sensitive electronics or explosive materials are handled.

Conclusion

In conclusion, static electricity hazards in industry can have severe consequences, including fires, equipment damage, contamination, and safety risks for personnel. Employing SSD Static Elimination Equipment is crucial to mitigate these hazards and maintain a safe and efficient work environment. Understanding the risks associated with static electricity and taking appropriate preventive measures is essential for all industries.